Supplier evaluation

How to become a Groupe Rocher Supplier

1) First Contact & Proposal Review & Business Interest Confirmation

- Business needs & expectations from GR

- Supplier know-how & added value

- Business proposal & feed-back

3) Supplier Selection Process

- Based on :

- supplier capabilities (quality, service, delivery lead-time & agility, sustainability, cost & cash, willingness to cooperate)

- product / service proposal and its’ match with GR expectations

2) Assessment of New Supplier

- Supplier background, references & reputation

- Group Rocher Supplier Code of Conduct signed / ethics@yrnet.com

- Supplier Financial Health check

- Supplier Capacity check (cost, quality, service, production capacity)

- Sustainability, Health & Safety risk assessment

4) Conclusion of Contract & Purchasing Agreement

- General procurement terms & conditions are thoroughly shared

- Procurement Framework contract defined and signed by both parties

- Specific SLA are defined & agreed

Supplier evaluation

We aim to create sustainable supply chain to face the challenges of today & tomorrow.

As such, we conduct supplier assessments and monitoring on a regular basis to ensure the strength of our supply chain.

Step 1

Before Starting Business

- Supplier background, references & reputation

- Group Rocher Supplier Code of Conduct signed

- Supplier Financial Health check

- Supplier Capacity check (cost, quality, service, production capacity)

- Sustainability, Health & Safety risk assessment

Step 2

New Business Award

- 6 Axes evaluation (Daisy) : partnership, CSR, quality, service, innovation, cost & cash

Step 3

Assessment on Run

- Group Rocher Supplier Code of Conduct and Contract signed

- Supplier Financial Health check

- Supplier Capacity check (cost, quality, service, production capacity)

- Sustainability, Health & Safety risk assessment

- Conformity Audit

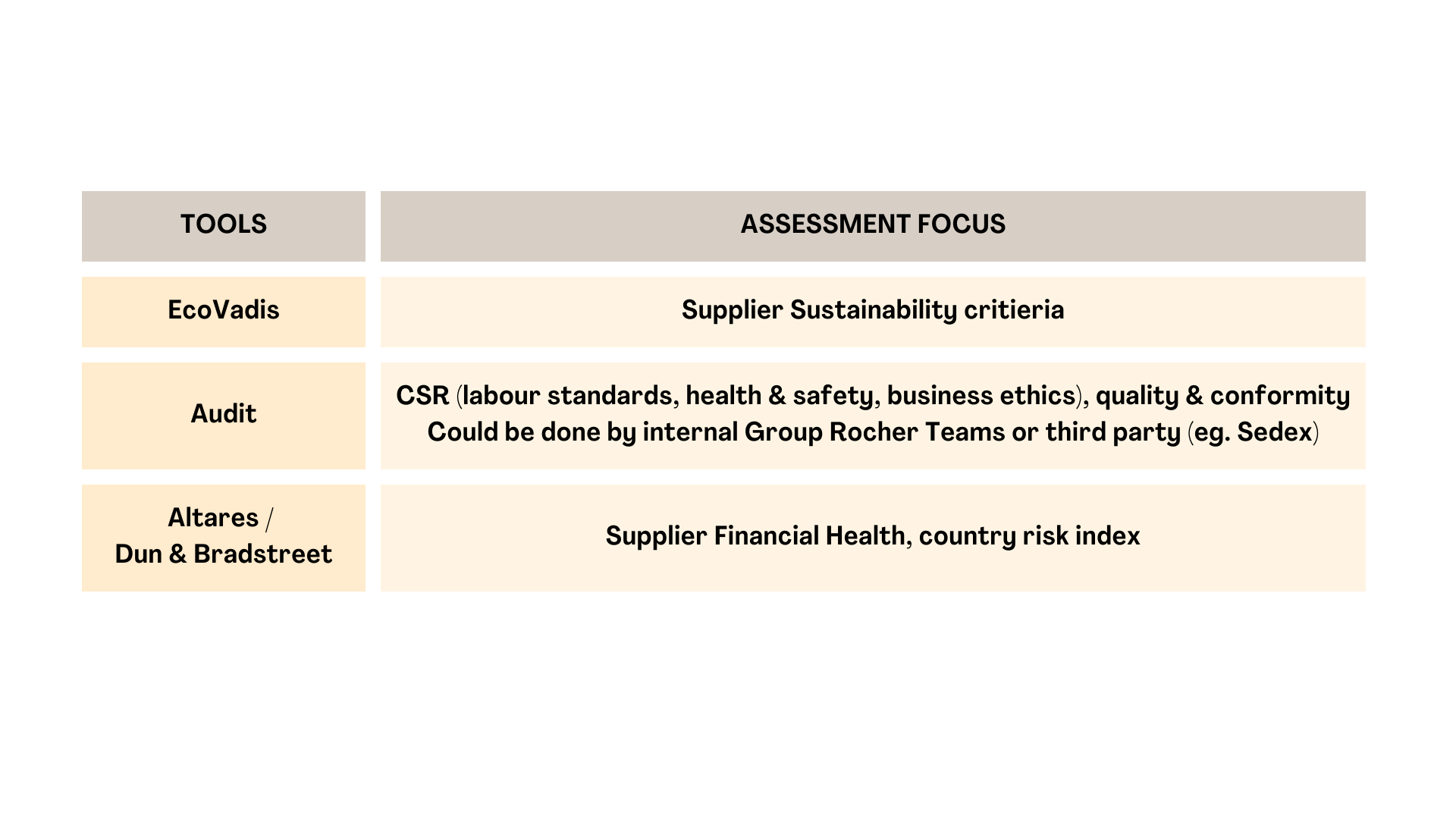

Here are the evaluation tools used by the group